Environmental Management

RATCH has deployed sustainable approaches when it comes to environmental management, to ensure the maximum efficiency and benefits of resource utilization and to prevent impacts and harms on the environment and natural resources. The environmental quality monitoring has been in place to control pollutants and waste from the production. On top of that, the Company aims to completely follow environmental rules and laws and exceed regulatory requirements.

Environmental and Social Policy

RATCH determines to shape the operation and execution of all work processes and activities in line with the Environmental and Social Policy. The policy will guide the feasibility study process of new projects, M&A due diligences and the evaluation of key suppliers of the Company, subsidiaries and operational controlled ventures in Thailand and abroad. RATCH will also encourage non-controlled joint ventures and other relevant parties in the supply chain in Thailand and abroad to operate with social and environmental responsibility and uses this policy as operational guidelines or apply this policy as deemed appropriate.

| Environmental and Social Policy’s key environmental aspects |

|---|

|

More Info: Environmental and Social Policy

RATCH’s power plants have generated electricity from fossil and renewable energy sources, with independent power producer (IPP) and small power producer (SPP) plants utilizing fossil fuels for the generation of a large quantity of electricity (83% of the Company Group’s net output). The choices of fuels are determined by power demands or as ordered by the National Command Center. Meanwhile, the output from renewable energy sources (17% of the Company Group’s net output) depends on natural conditions.

The production process requires water as a major raw material as power plants need water for the cooling system, demineralized water for boilers, etc. The power plants rely on two water withdrawal patterns: direct withdrawal from water sources like surface water (rivers and canals) and groundwater; and purchases of raw water or processed water like tap water. Both patterns take into consideration the water stress in the localities.

In 2024, the number of the Company Group’s power plants in the scope of environmental data reporting totaled 7, with 770-MW Hin Kong Power Plant Block1 being added into the portfolio in the year. All plants generated 62.05% of total revenue.

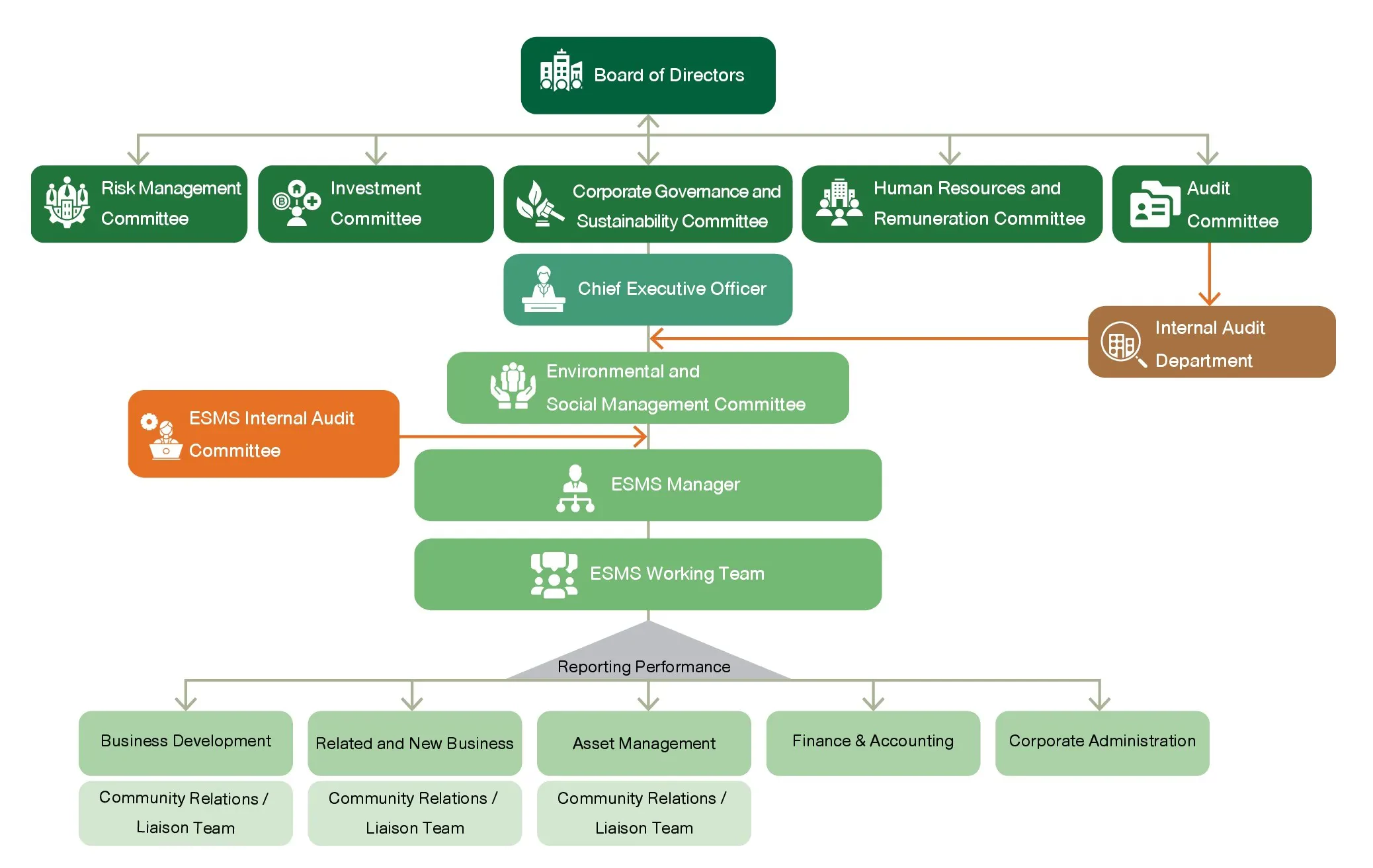

Supervision of Environmental Operations

Under the Environmental and Social Management System (ESMS), RATCH has enforced the Environmental and Social Policy and assigned all personnel in line with the ESMS supervision structure, to drive the endeavor and ensure compliance with the manual and prescribed procedure. All functions are required to report their operations to the Board of Directors and relevant working committees for continuous improvements.

ESMS Management Structure

RATCH ESMS Framework

The PDCA (Plan-Do-Check-Act) model is applied for systematic work processes, to ensure continuous improvements on efficiency and environmental and social operations as well as alignment with requirements.

Resource and energy consumption

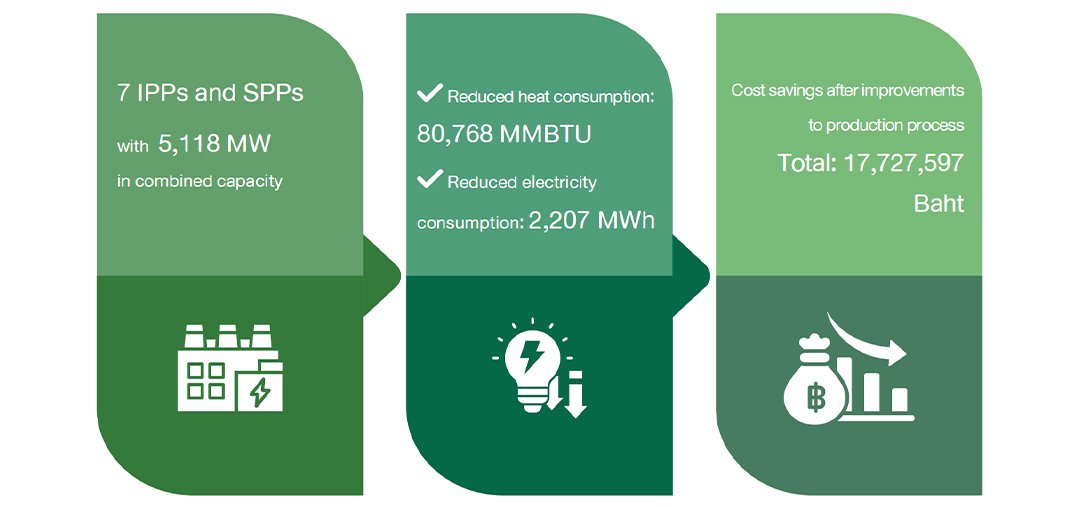

RATCH controlled the operations of 7 power plants in Thailand in 2024 (with combined capacity of 5,118 MW). They are Ratchaburi Power Plant, Berkprai Cogeneration Power Plant, Nava Nakorn Electricity Generating Power Plant, RATCH Cogeneration Power Plant, Ratch Energy Rayong Power Plant, Ratch Pathana Energy Power Plant, and Hin Kong Power Plant. Their natural gas and electricity consumption generated 100,976 million megajoules of electric power and steam, which can be classified below:

- Generated electric power totaling 48,919 million megajoules (13,588,671 megawatt-hours)

- Distributed electric power and steam totaling 47,622 million megajoules (13,228,268 megawatt-hours) and 1,301 million megajoules (466,328 tons), respectively.

At Ratchaburi Power Plant of which installed capacity is 3,645 MW, only 3 combined cycle generators, each with 725 MW capacity, were operational in 2024, using natural gas as fuel. Two generating units with 735 MW capacity each were on reserve shutdown.

| List | Unit | 2024 | 2023 | 2022 |

|---|---|---|---|---|

| Natural gas | Million Cubic Feet | 98,991 | 87,674 | 149,202 |

| Million Megajoule | 100,970 | 89,428 | 152,186 | |

| Bunker oil | Liter | 0 | 92,755,799 | 290,691,483 |

| Million Megajoule | 0 | 3,689 | 11,561 | |

| Diesel oil | Liter | 153,445 | 6,168,914 | 21,881,178 |

| Million Megajoule | 6 | 225 | 797 | |

| Energy use from transmission system | MWh | 52,172 | 40,813 | 46,905 |

| Million Megajoule | 188 | 147 | 169 | |

| Renewable energy use | MWh | 17,085 | 16,600 | 13,860 |

| Million Megajoule | 62 | 60 | 50 | |

| Total produced electricity | MWh | 13,588,671 | 11,141,093 | 18,958,341 |

| Million Megajoule | 48,919 | 40,108 | 68,250 | |

| Total distributed electricity | MWh | 13,228,268 | 10,842,852 | 18,488,776 |

| Million Megajoule | 47,622 | 39,034 | 66,560 | |

| Total distributed steam | Tons | 466,328 | 459,544 | 475,252 |

| Million Megajoule | 1,301 | 1,292 | 1,338 |

Guidelines and targets for fuel and energy utilization

| Factors to Consider | Operational Guidelines | 2024 Target | Performance in 2024 |

|---|---|---|---|

| Designing of combustion system |

|

Each power plant’s heat rate meets their specified levels.

|

Heat rates met the power plants’ specified levels.

|

| Machinery/Equipment readiness |

|

All power plants can maintain machinery/equipment in line with the planned outage. | Maintenance works at all power plants in 2024 were carried out as planned. |

| Production efficiency |

|

All power plants can meet their targets on the reduction of energy/fuel utilization. | All power plants met their targets in enhancing production efficiency through the reduction in energy/fuel utilization (100%). Average production efficiency is at 43.67-67.34%. |

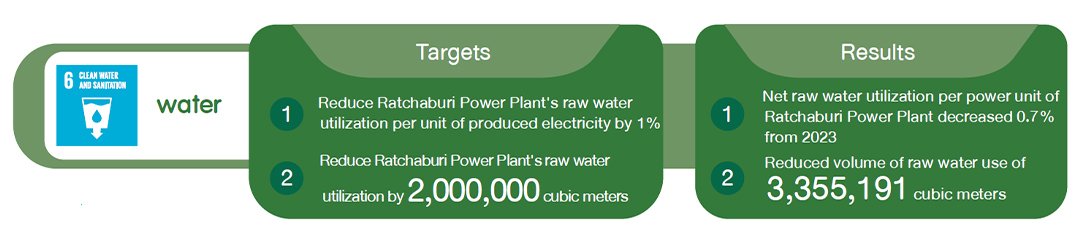

Water management

Climate change has affected the quantity and quality of water sources, as it induces both drought and flooding, aside from seasonal saltwater intrusion. Water resource management is a must for RATCH Group in preparation for the situations that may affect water withdrawals for electricity generation, which can impact revenue and lead to a fight for water with community or farmers.

As part of the Environmental and Social Management System (ESMS), RATCH devised the Water Risk Assessment Procedure. It serves as a risk assessment tool based on the criteria of WWF Water Risk Filter and World’s Resources Institute (WRI) Aqueduct Water Risk Atlas, which analyzes likely impacts based on legal requirements, financial aspects, raw water volume, water quality, utilization balance and relevant stakeholders. The results are the basis for the water management plan.

Water stress assessment and water management

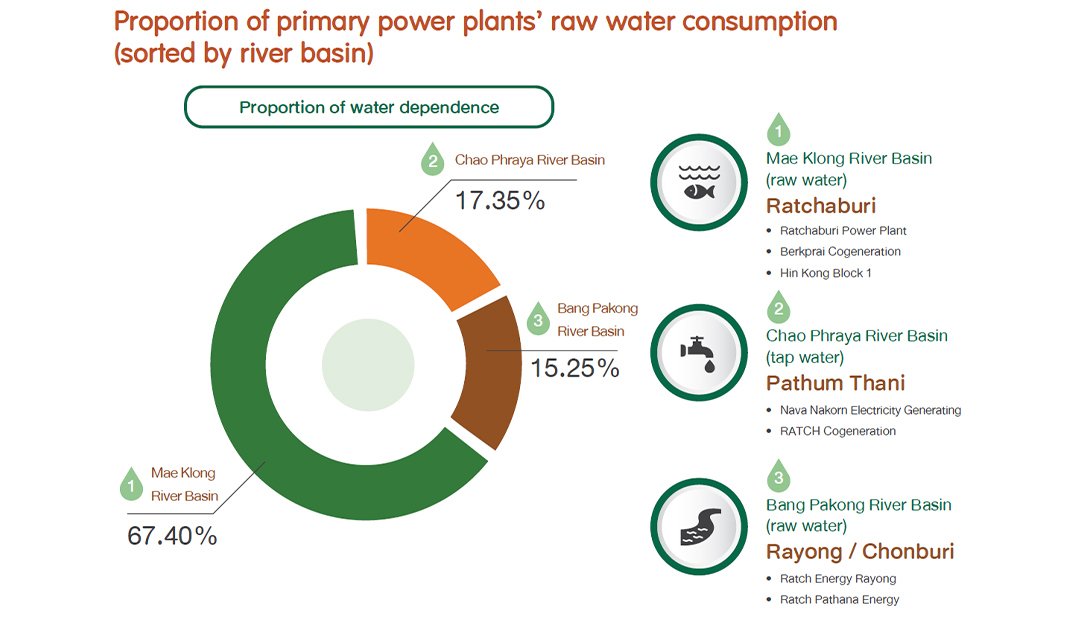

The Mae Klong River Basin, the Chao Phraya River Basin, and the Bang Pakong River Basin remained the primary water sources for RATCH Group’s operations in 2024. Power plants in Ratchaburi province withdrew water directly from the Mae Klong River for their production, while those in Chonburi and Rayong provinces used water from the Bang Pakong River. Meanwhile, power plants in Pathum Thani province used tap water that suppliers produced from water in the Chao Phraya River Basin.

The assessment in 2024 showed a high-water stress level (at 40-80%) in the Chao Phraya River Basin and the Bang Pakong River Basin and the guidelines to manage risks and water utilization were launched, to keep power plants’ generation capacity intact without having to fight for water.

Risk and water utilization management guidelines

The guidelines for power plants using raw water or tap water from the river basins with high water stress level are as follows:

- Nava Nakorn Generating Power Plant (NNEG) and RATCH Cogeneration Power Plant, located in PathumThani province and withdrawing raw water from the Chao Phraya River Basin for generation process, entered 25-year tap water supply contracts (through end of the power plants’ life cycle).

- Ratch Pathana Energy Power Plant (formerly Sahacogen (Chonburi)) in Chonburi province and Ratch Energy Rayong Power Plant in Rayong province used raw water from Bang Pakong River Basin through raw water suppliers with 10-year and 25-year supply contracts, respectively.

- The power plants with raw water or tap water supply contracts required the suppliers prepare secondary and emergency water sources, to ensure power generation continuity in case of drought or water shortage in the river basins.

- Reserve ponds or secondary storage system were in place for at least 10 days of internal use, along with water quality improvement systems.

- Water cycles in the cooling system were optimized, to reduce raw water withdrawal.

- Water reuse cycles for internal use were optimized, e.g. reusing RO-treated wastewater in the production process or using rainwater for production, and equipment cleaning/tree watering purposes.

- Water pipelines were regularly inspected to prevent the leakage and loss of raw and tap water.

Water reuse in production process

All power plants set the target to maintain and increasing water cycles in the cooling system at their best efforts, to minimize the withdrawal of raw water. A number of 7 power plants (contributing 62.5% of fossil fuel-based generation capacity) succeeded in this endeavor.

| Powerplant | Location | Water Cycle Target | Average Water Cycle |

|---|---|---|---|

| Ratchaburi Thermal Plant 2 Units (735 MW/Unit, total 1,470 MW) |

Ratchaburi | Unable to set target due to inconsistent production |

- |

| Ratchaburi Combined Cycle Plant 3 Units (725 MW/Unit, total 2,175 MW) |

4-6 | 4.88 | |

| Hinkong Block 1 (770 MW) | 4-5 | 4.27 | |

| Berkprai Cogeneration (99.46 MW) | 3-5 | 3.58 | |

| Nava Nakorn 2 Units (201.57 MW) | Pathum Thani | 4 | 4.37 |

| RATCH Cogeneration (119.75 MW) | 6 | 7.77 | |

| RATCH Cogeneration (Expansion Phase) (31.2 MW) | 5 | 5.93 | |

| RATCH Energy Rayong (98 MW) | Rayong | 5-10 | 6.26 |

| RATCH Pathana Energy (153 MW) | Chonburi | 5-13 (Block 1) | 6.78 |

| 3-8 (Block 2-3) | 4.70 |

At Ratchaburi Power Plant which is the Company’s primary IPP plant (with 3,645 MW capacity), there have been continuous efforts to lower raw water withdrawal particularly for 3 combined cycle units which were operational all year. The goal was to bring down the water stress level in the Mae Klong River Basin. In 2024, the power plant reduced raw water consumption by 3,355,191 cubic meters.

Water consumption (Ratchaburi Power Plant)

| Actions to reduce consumption | Equivalent to reduced raw water withdrawal (cubic meters) | Reduced volume in total (cubic meters) | Target (cubic meters) |

|---|---|---|---|

| Water cycles in cooling system | 2,360,317 | 3,355,191 | 2,000,000 |

| Reuse of RO-treated wastewater | 304,425 | ||

| Reuse of treated water for equipment cleaning/tree watering purposes | 690,449 |

Water balance analysis

| Power Plant | Water Source | Water Stress Level | Water Utilization | Discharge Volume | Net water utilization (raw water-water discharge) | Water use per power unit (cubic meter/ MWh) | Power output (%) | ||

|---|---|---|---|---|---|---|---|---|---|

| Low-Medium (10-20%) | Medium-High (21-40%) | High (41-80%) | Million Cubic Meters | ||||||

| Ratchaburi | Mae Klong River | - | ✔ | - | 4.57 | 1.14 | 3.44 | 1 | 34.45 |

| Berkprai | - | ✔ | - | 0.91 | 0.27 | 0.64 | 1.49 | 4.62 | |

| Hinkong (Unit 1) | - | ✔ | - | 5.21 | 1.31 | 3.91 | 1.07 | 36.73 | |

| Nava Nakorn Electricity Generating | Tap water from the Chao Phraya River | - | - | ✔ | 1.81 | 0.62 | 1.19 | 1.61 | 8.48 |

| RATCH Cogeneration | - | - | ✔ | 0.94 | 0.19 | 0.75 | 1.24 | 5.78 | |

| RATCH Energy Rayong | Bang Pakong River Basin | - | - | ✔ | 0.71 | 0.12 | 0.59 | 1.17 | 4.59 |

| RATCH Pathana Energy | - | - | ✔ | 1.71 | 0.54 | 1.17 | 2.42 | 5.35 | |

Waste management

The 3R principles - Reduce, Reuse and Recycle - remained the heart of waste management, for both hazardous and non-hazardous waste from the production process, maintenance processes and office building activities. RATCH’s goal is to achieve zero waste to landfill and targets were recently set to reduce the Company Group’s non-hazardous waste.

Target and waste management guidelines

| Targets | Waste management guidelines | |

|---|---|---|

| Hazardous waste | Zero Hazardous Waste to Landfill |

|

| Non-hazardous waste |

Songkhla Biomass Power Plant

RATCH Group’s

|

|

Results of power plants’ waste management

In 2024, the 7 power plants that contributed 62.05% of annualized revenue recovered 2.11% of waste and disposed 97.89% of waste. In 2025, the Hin Kong Power Plant will repurpose sludge from the water treatment system for recovery operations instead of disposal operations. Details are as follows:

| Method | Operation | Waste Volume (ton) | Total Volume (ton) | % | |

|---|---|---|---|---|---|

| Non-Hazardous | Hazardous | ||||

| Converting waste through recovery process (2.11%) | Reuse | 0 | 0 | 0 | - |

| Recycle e.g. stationary waste (glass, paper, plastic) | 6.25 | 20.85 | 27.10 | 1.03 | |

| Other Recovery Operations e.g. rubble from construction work, used lubricating oil | 22.44 | 6.99 | 29.43 | 1.10 | |

| Waste disposal (97.89%) | Incineration with Energy Recovery e.g. oil-contaminated rags | 0.60 | 25.76 | 26.36 | 0.99 |

| Incineration without Energy Recovery e.g. oil-contaminated waste | 0 | 27.39 | 27.39 | 1.02 | |

| Landfilling e.g. water treatment sludge | 2,224.74 | 37.57 | 2,262.31 | 84.62 | |

| Other Disposal Operations e.g. sludge | 17.85 | 283.02 | 300.87 | 11.25 | |

Air quality management

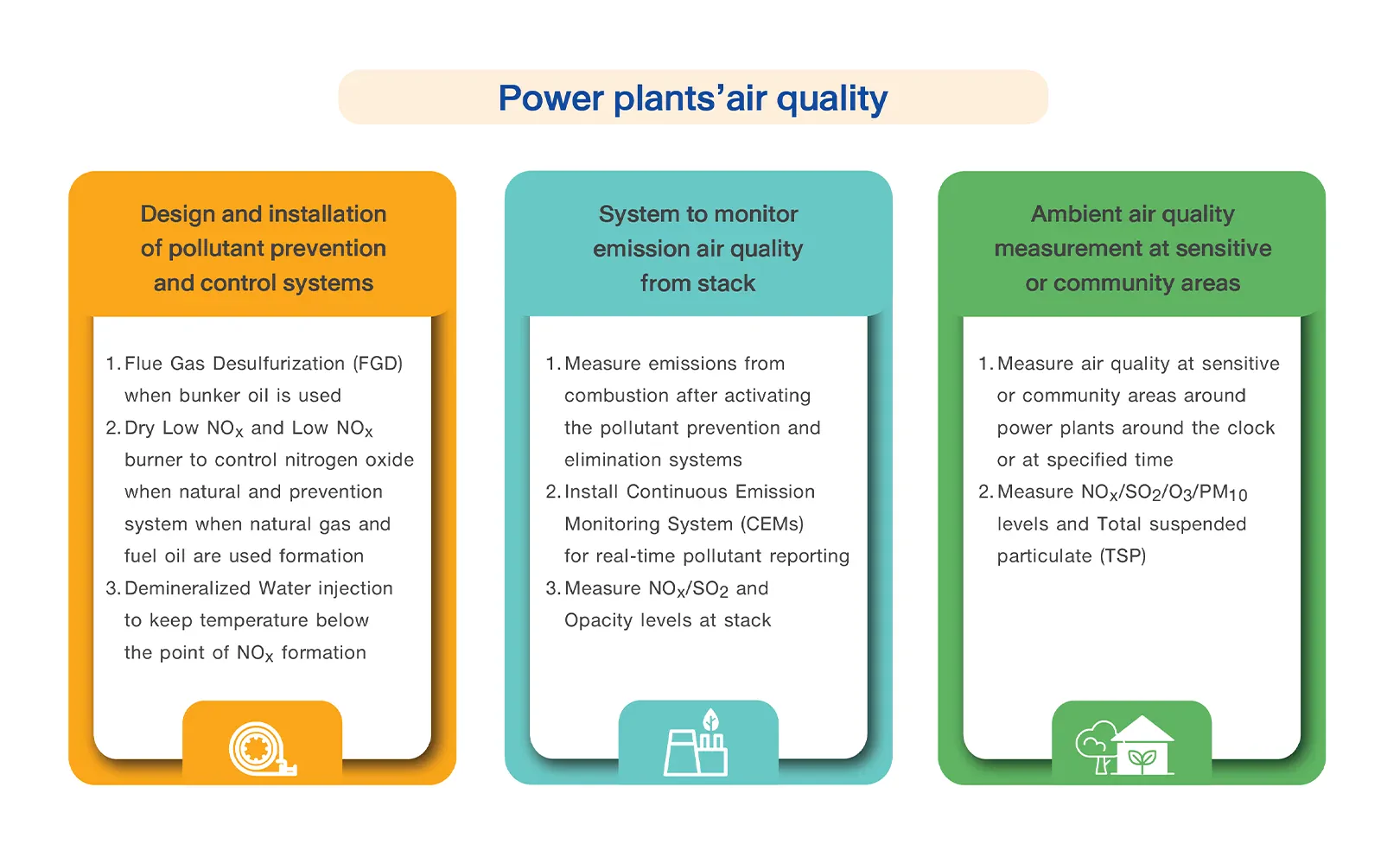

Thermal and combined cycle power plants need a system to emit contaminated combustion air to the atmosphere. It is thus necessary to tackle significant pollutants – sulfur dioxide and nitrogen oxide – and strictly keep them within legal emission permissible limits.

Air quality at stack of Thailand-based power plants

All 7 power plants in Thailand under RATCH’s operating control (contributing 62.05% of total revenue) consistently measured combustion-related pollutants via the Continuous Emission Monitoring Systems (CEMS) or the collection of random samples from stack for pollutant measurement. In 2024, the pollutants at all power plants remained within permissible levels and in line with targets. CEMS are inspected for their accuracy by external verifiers on an annual basis, to affirm the accuracy and reliability of reports submitted to the governing or regulatory body.

Ratchaburi Electricity Generating Co., Ltd, RATCH’s wholly owned subsidiary, taken into account for air emission as the Corporate KPIs primarily taking care by the Safety, Environment and Risk Management Division reporting directly to Managing Director who is supervised by Chief Asset Management Officer of Ratch Group

| Power Plant | Average concentration of pollutants from combustion | ||||

|---|---|---|---|---|---|

| NOX (ppm) | SO2 (ppm) | Secondary fuel | |||

| Natural gas | Fuel oil | Natural gas | Fuel oil | ||

| Ratchaburi Thermal | Reserved shutdown | Bunker oil | |||

| Ratchaburi Combine Cycle | 33.7 | - | 2.72 | - | Diesel oil |

| Target (below legal limits) * | 120 | 180 | 20 | 320 | - |

| Hinkong Unit 1 | 45.33 | 0 | 0.59 | 0 | Diesel oil |

| Target (not exceeding EIA-specified limits) | 59 | 99 | 10 | 20 | - |

| Berkprai Cogeneration | 34.29 | - | <0.1 | - | None |

| RATCH Cogeneration | 42.01 | - | <1 | - | None |

| Nava Nakorn Electricity Generating | 24.79 | - | 0.67 | - | None |

| RATCH Energy Rayong | 37.82 | - | 0.51 | - | None |

| Target (not exceeding EIA-specified limits) | 60 | - | 10 | - | - |

| RATCH Pathana Energy HRSG4# | 58.77 | - | 0.57 | - | None |

| Target (not exceeding EIA-specified limits) | 108 | - | 18 | - | - |

| RATCH Pathana Energy HRSG5# | 20.54 | - | 0.36 | - | None |

| Target (not exceeding EIA-specified limits) | 90 | - | 15 | - | - |

| RATCH Pathana Energy HRSG6# | 41.78 | - | 0.34 | - | None |

| Target (not exceeding EIA-specified limits) | 60 | - | 10 | - | - |

| Note : | * Standard limits as in the B.E. 2547 Notification of Ministry of Industry on the limit of air pollutants emitted by power-generating, transmission or distribution plants. |

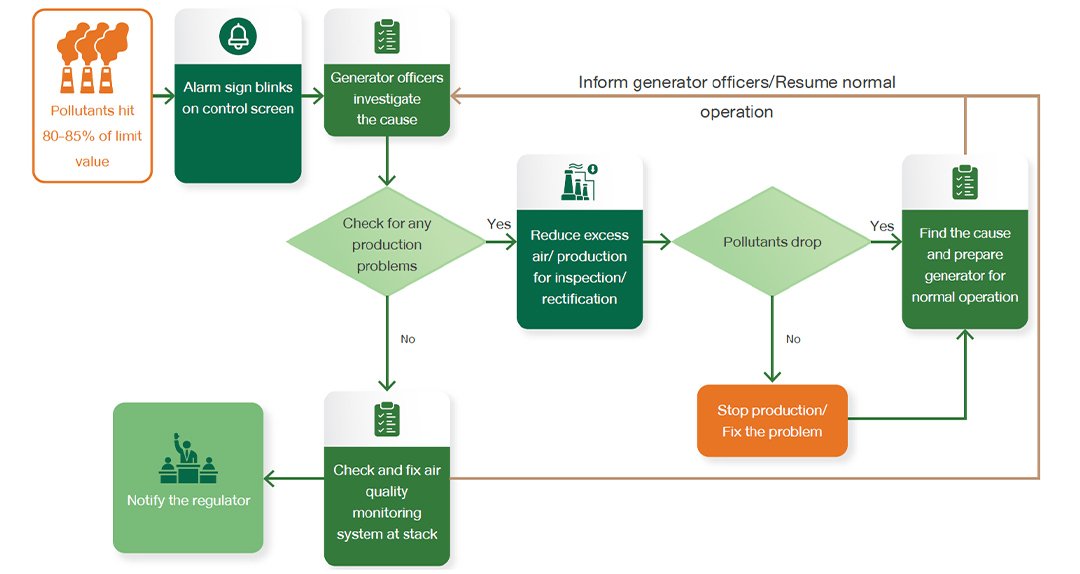

Continuous Emission Monitoring Systems (CEMS)

The power plants place a warning system to alert all involved when reported pollutants at stack hit 80-85% (High Alarm) or 95% (High High Alarm) of standard limits. The alarm sign will blink on control screens and controllers promptly check the production process and the monitoring system’s accuracy. Irregularities will be fixed as soon as possible while the regulator and relevant offices are notified of the incident. If the irregularities remain, the power plants will reduce production or eventually stop production until the situation returns to normal.

Warning system

Ambient air quality monitoring in community

In 2024, all the 7 power plants monitored the ambient air quality at monitoring stations located in neighboring community, during the seasonal periods as specified in EIA or EHIA. At Ratchaburi Power Plant, given its large size, the Ambient Air Quality Monitoring Systems (AAQMs) is installed at 4 locations around the power plant for 24-hour continuous measurement monitoring. AAQMs were tested for efficiency and accuracy every year by external inspectors.

| The power plant’s result of air quality monitoring | 24-hour average | 1-hour average | ||||

|---|---|---|---|---|---|---|

| "Total" suspended particulate (μg/m3) | Particulate matter smaller than 10 microns (μg/m3) | SO2 (ppb) | SO2 (ppb) | NO2 (ppb) | O3 (ppb) | |

| Ratchaburi | 9-132 | 8-122 | 0-6 | 0-8 | 0-41 | 0-138 |

| Hinkong Unit 1 | 17-100 | 5-46 | 4-5 | 4-6 | 3-12 | Not monitored |

| Berkprai Cogeneration | 21-84 | 7-50 | 0.8-4.2 | 0.1-5.5 | 1.5-19.8 | Not monitored |

| RATCH Cogeneration | 33-154 | 13-94 | 2.6-4.8 | 1.6-6.3 | 11.9-24.7 | 13.9-29.8 |

| Nava Nakorn Generating | 14-213 | 8-116 | 1.2-6.4 | 0-7.2 | 0.7-27 | Not monitored |

| RATCH Energy Rayong | 19-89 | 9-44 | <1-9.9 | <1-24 | <1-19.6 | Not monitored |

| RATCH Pathana Energy | 32-433 | 19-167 | <1-68 | 1-68 | 1-38 | Not monitored |

| Target (below legal limits*) | 330 | 120 | 120 | 300 | 170 | 100 |

| Note : | μg/m3 = microgram per cubic meter, ppb = part per billion |

| * Standard levels in line with the Notifications of National Environment Board, No.21, No. 24, No. 28 and No. 33 |

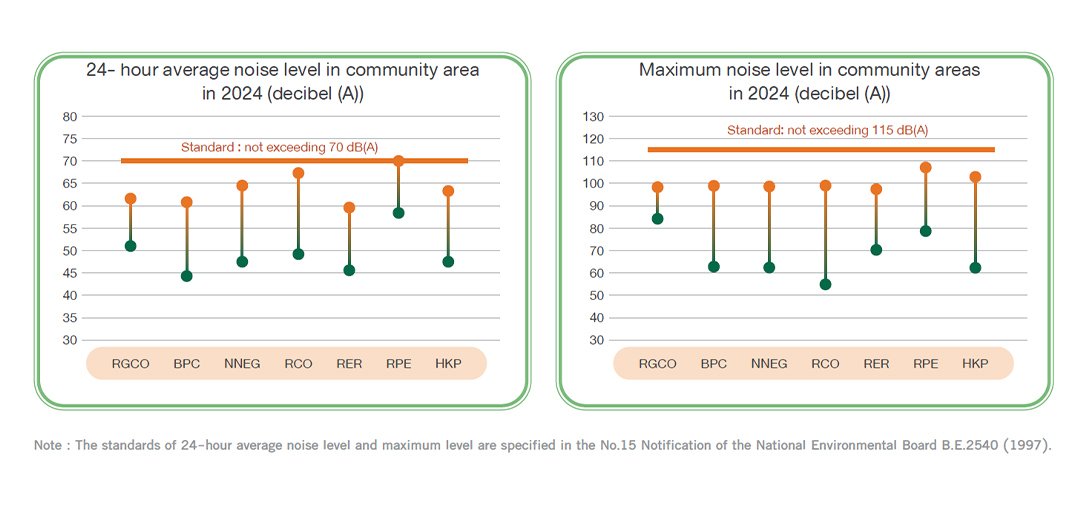

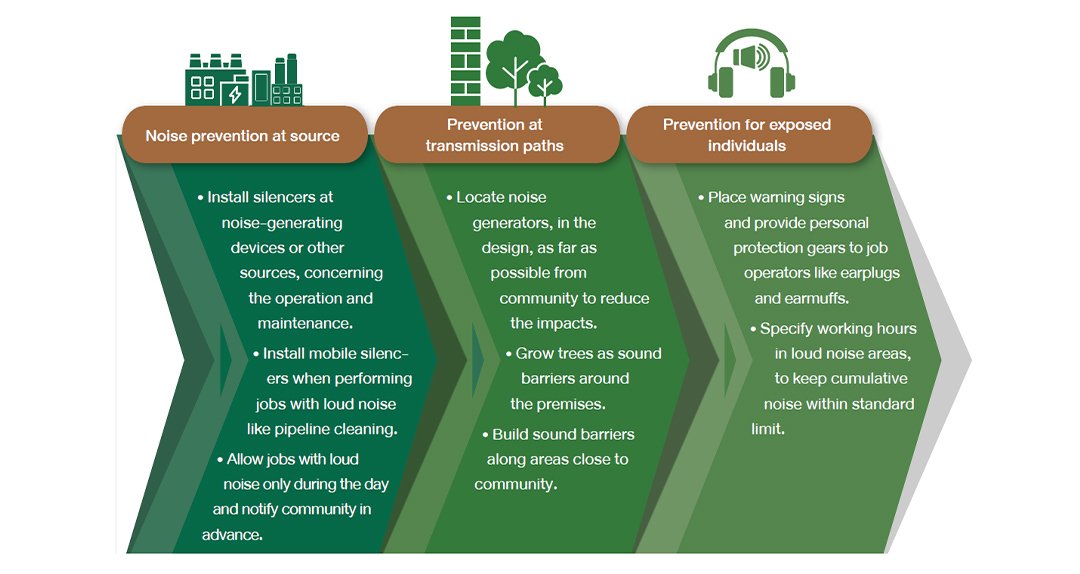

Noise management

Noise generated by construction works and the operations and maintenance of power plants may cause impacts on community and living organisms as well as job operators in the areas. All power plants are thus equipped with noise control systems or devices that reduce noise at source, aside from other prevention measures that depend on the project’s conditions and the affected. The measures are set to deal with noise in 3 aspects: sources of noise, transmission paths and individuals exposed to the noise.

Results of noise level monitoring in 2024

All 7 RATCH operational-controlled power plants in Thailand (contributing 62.05% of total revenue in 2024) were able to control noise impacts in line with EIA measures. The average noise level and maximum noise level in 2024 at the power plants and in community were within standard limits and did not cause impacts on community.