Water Related Risks

Climate change has affected the quantity and quality of water sources, as it induces both drought and flooding, aside from seasonal saltwater intrusion. Water resource management is a must for RATCH Group in preparation for the situations that may affect water withdrawals for electricity generation, which can impact revenue and lead to a fight for water with community or farmers.

As part of the Environmental and Social Management System (ESMS), RATCH devised the Water Risk Assessment Procedure. It serves as a risk assessment tool based on the criteria of WWF Water Risk Filter and World’s Resources Institute (WRI) Aqueduct Water Risk Atlas, which analyzes likely impacts based on legal requirements, financial aspects, raw water volume, water quality, utilization balance and relevant stakeholders. The results are the basis for the water management plan.

Water stress assessment and water management

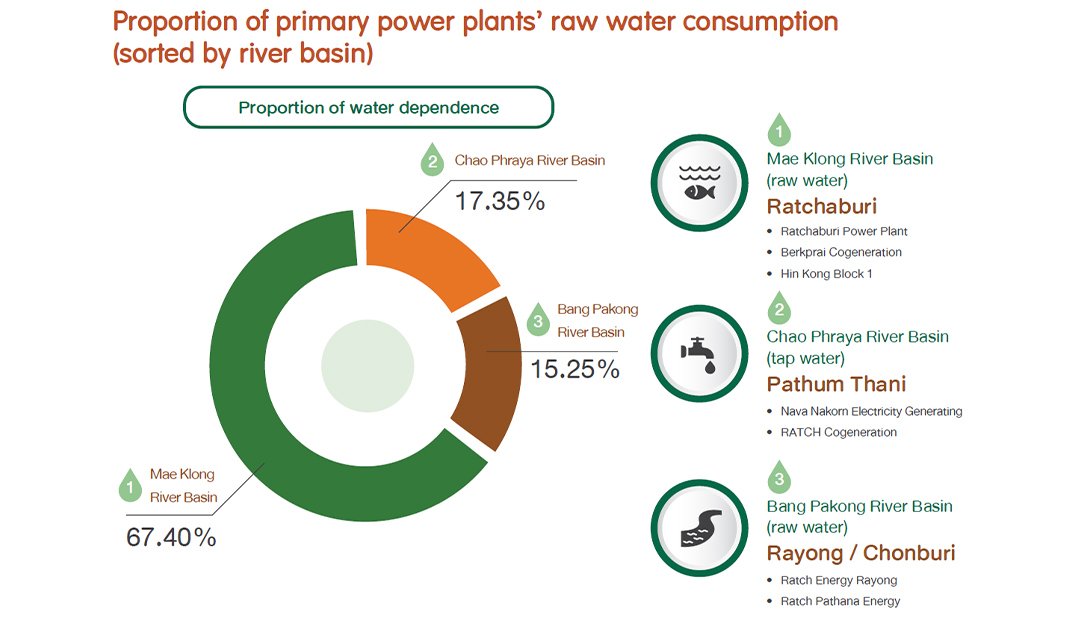

The Mae Klong River Basin, the Chao Phraya River Basin, and the Bang Pakong River Basin remained the primary water sources for RATCH Group’s operations in 2024. Power plants in Ratchaburi province withdrew water directly from the Mae Klong River for their production, while those in Chonburi and Rayong provinces used water from the Bang Pakong River. Meanwhile, power plants in Pathum Thani province used tap water that suppliers produced from water in the Chao Phraya River Basin.

The assessment in 2024 showed a high-water stress level (at 40-80%) in the Chao Phraya River Basin and the Bang Pakong River Basin and the guidelines to manage risks and water utilization were launched, to keep power plants’ generation capacity intact without having to fight for water.

Risk and water utilization management guidelines

The guidelines for power plants using raw water or tap water from the river basins with high water stress level are as follows:

- Nava Nakorn Generating Power Plant (NNEG) and RATCH Cogeneration Power Plant, located in PathumThani province and withdrawing raw water from the Chao Phraya River Basin for generation process, entered 25-year tap water supply contracts (through end of the power plants’ life cycle).

- Ratch Pathana Energy Power Plant (formerly Sahacogen (Chonburi)) in Chonburi province and Ratch Energy Rayong Power Plant in Rayong province used raw water from Bang Pakong River Basin through raw water suppliers with 10-year and 25-year supply contracts, respectively.

- The power plants with raw water or tap water supply contracts required the suppliers prepare secondary and emergency water sources, to ensure power generation continuity in case of drought or water shortage in the river basins.

- Reserve ponds or secondary storage system were in place for at least 10 days of internal use, along with water quality improvement systems.

- Water cycles in the cooling system were optimized, to reduce raw water withdrawal.

- Water reuse cycles for internal use were optimized, e.g. reusing RO-treated wastewater in the production process or using rainwater for production, and equipment cleaning/tree watering purposes.

- Water pipelines were regularly inspected to prevent the leakage and loss of raw and tap water.